Industrias

345097448

UNINSA

345096555

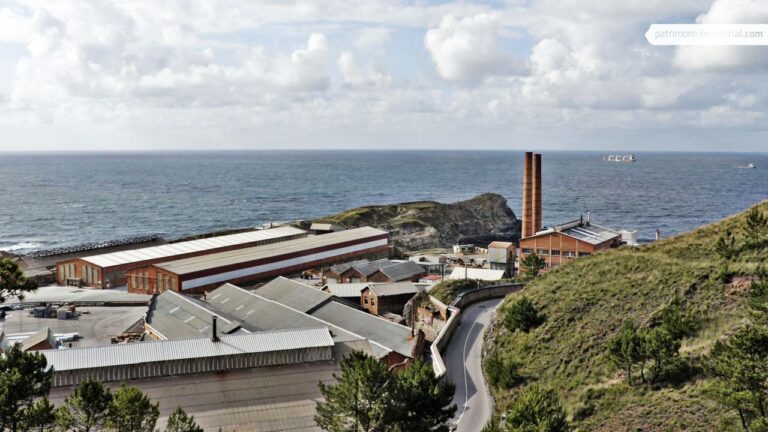

UNINSA - Blast Furnaces

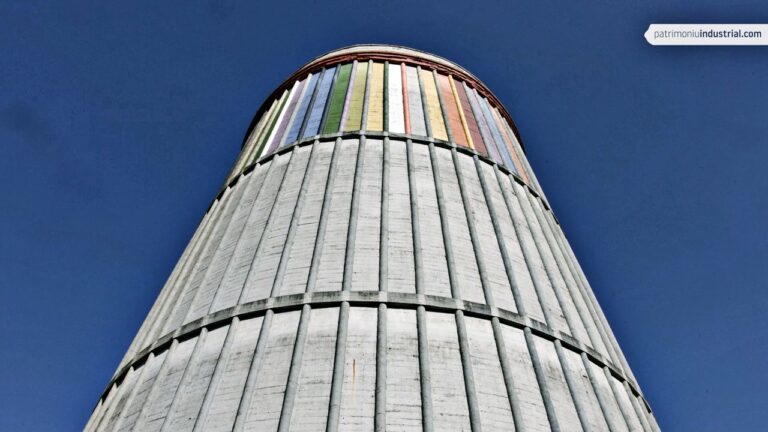

Static giants of almost one hundred metres tall: the blast furnaces of the Veriña (Gijón) ferrous metallurgy plant are the heart of the iron and steel making process. They were designed to produce 3,400 tonnes of pig iron per day and their capacity determines the production of the entire factory.

The construction of the first blast furnace was completed in January 1971, and on the 6th May 1971 at 7.20 p.m., it was switched on to obtain its first casting five days later. As a key part of the ferrous metallurgy industry, the operation of the furnace and its complementary installations involves a carefully thought-out preparation system for raw materials, energy supply, loading, transport and cooling.

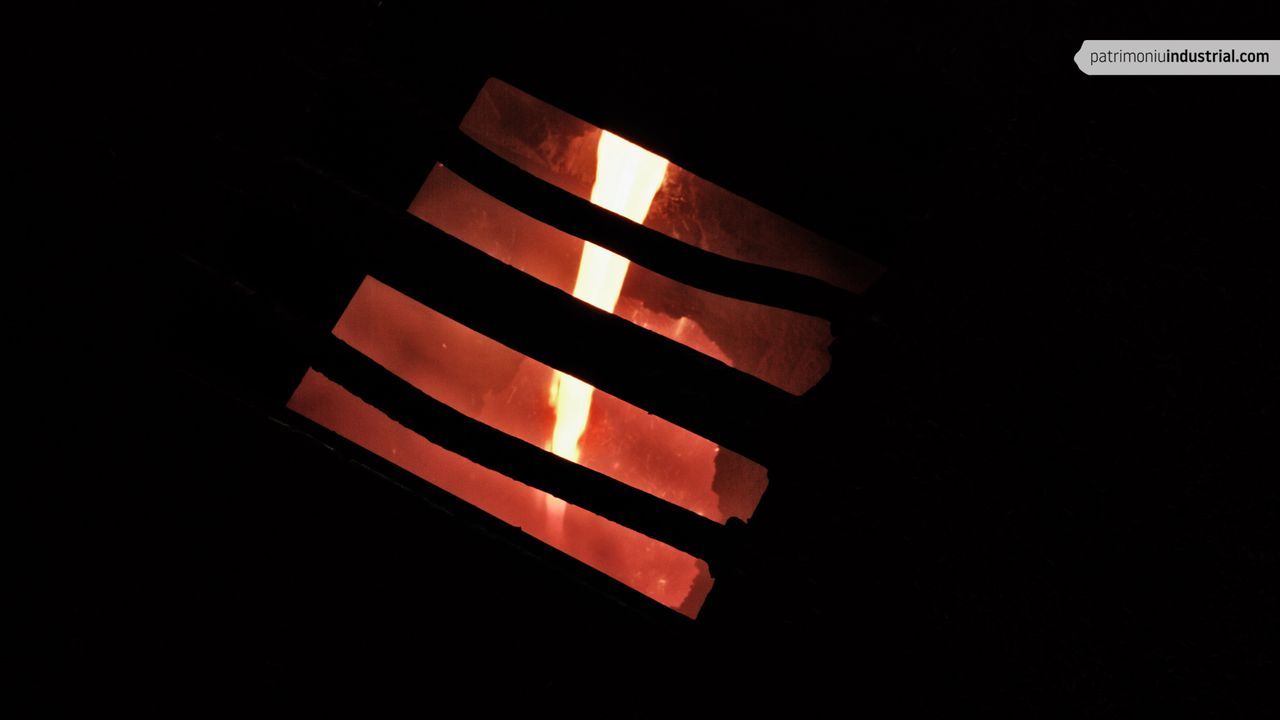

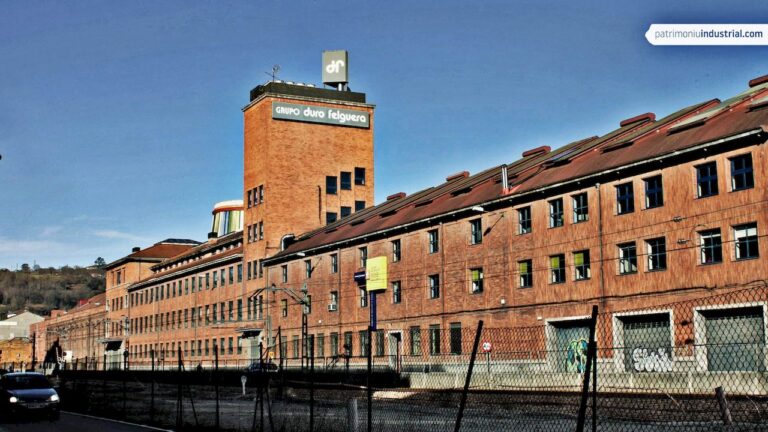

In the blast furnace, the pig iron is obtained by heating a mixture of iron ore, coke, sinter - a fine mixture of iron ore and limestone - and other fluxes. The load is fed into the upper part of the furnace. Meanwhile, in the lower part, the air needed for combustion is blown into the furnace by means of ducts. The coke, which acts as a reducing agent, is manufactured after a complex process of coal distillation carried out in the furnaces. The coke batteries at the Gijón factory were not installed until 1974 and 1977, since the supply was provided by those in operation at the historic plants of Duro Felguera, Fábrica de Mieres and Moreda-Gijón. The gases derived from the iron and steel making process are stored in gasometers after its purification and are partly used to heat the furnace heaters.

The resulting pig iron has a high iron content - around 95 % - and is 3,5 % carbon. It is separated from the slag in the crucible at the bottom of the furnace. After being extracted by casting and deposited on ladles or torpedo-ladles, the transformation of the pig iron into steel takes place in the converters of the steelworks, where the excess carbon is removed by oxygen blowing. It gets solidified in the continuous casting, obtaining different types of results, which, thanks to the rolling process, allow the transformed and final products to be obtained (flats, profiles, wire rod, rails and rounds).

Recent Comments